SAE J2334 is a cyclic test standard that requires the chamber to conform to SAE J1563, ASTM D 1735, and ASTM D2247. The solution for this test is comprised of .5% NaCl, .1% CaCl₂, .075% NaHCO₃, and the balance D.I. water. SAE J2334 allows for the solution to be sprayed onto the samples or the samples can be immersed under the solution for a set period of time. SAE J2334 is normally conducted for a minimum of 60 days. Mass loss coupons are placed in the test exposure zone to provide a measure of the corrosiveness of the test. These mass loss coupons are similar to the ones used in GMW 14872 testing.

Testing Certificate # 2563.02

Our lab is accredited by A2LA.Scope

A2LA Letter of Accreditation (PDF)

Benefits of ATC Test Lab

A2LA Accredited Test Lab

Specialized Testing Equipment and Chambers

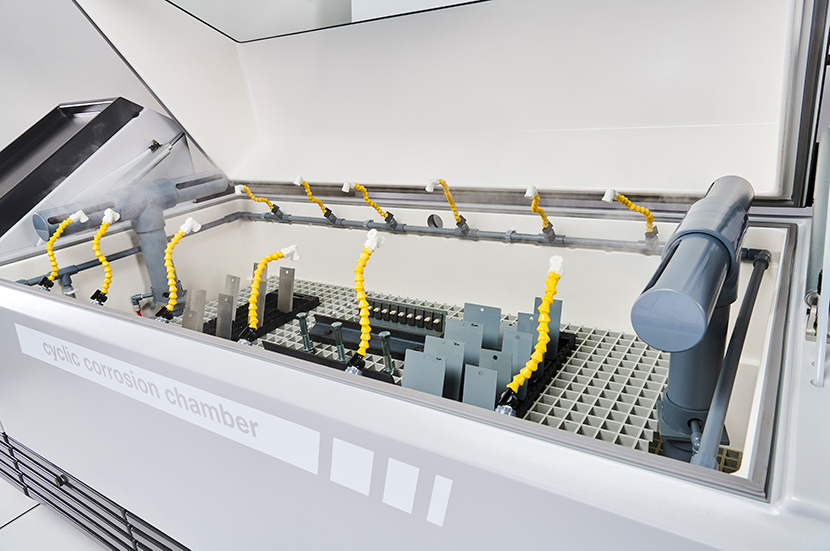

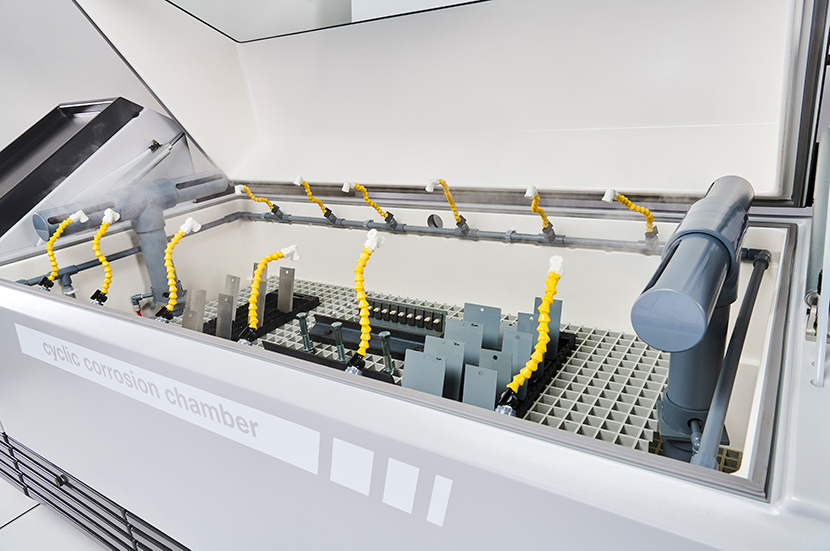

ATC has new state of the art equipment to perform the most advanced testing. We have over 1200 Cubic Feet of testing space available, and the largest testing chambers in the world.

By contracting us, you can save money on new costly equipment, maintenance, and down time. You can size and scale your tests based on your level of production.

Receive Photographs and Updates

The best way to monitor your products during the testing process is though digital photography. ATC Test Lab offers high resolution photos at your requested intervals. The use of photographs can help you save money if you need to stop the test early due to product failure or unusual corrosion.

SAE J2334 Cyclic Corrosion Resistance Testing Chamber at ATC Test Lab

SAE J2334

Cyclic Corrosion

Exposure Testing

ATC Test Lab is the Largest Contract Corrosion Test Lab.

- We have over 1200 cubic feet of testing space available.

- Large testing chambers

- Our lab has state of the art equipment to perform the most advanced testing.

- Experienced laboratory technicians conducting your tests.