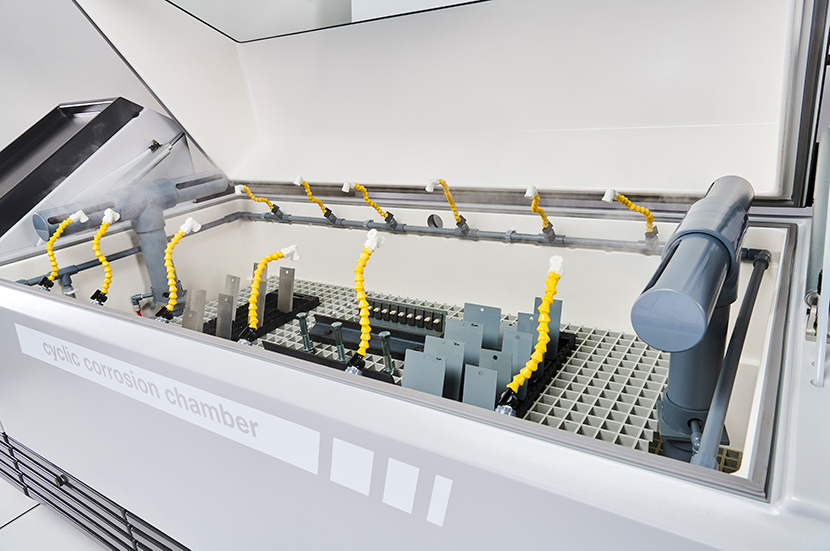

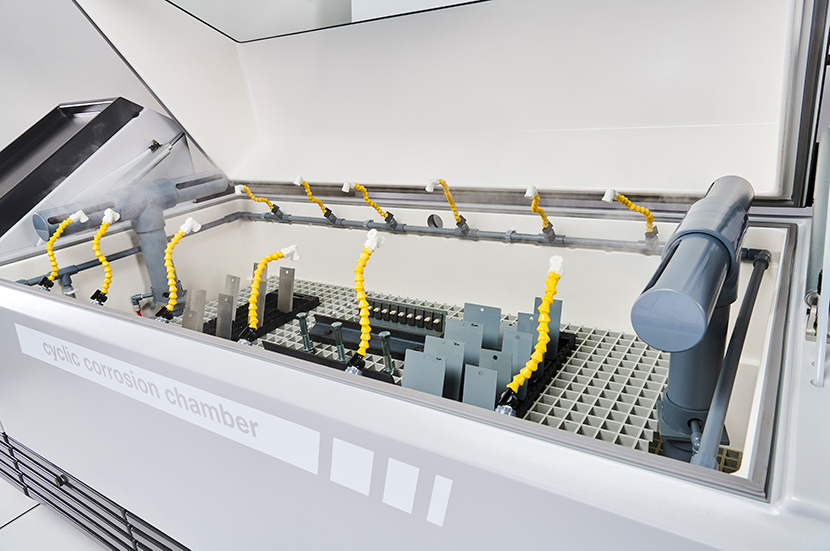

GMW 14872 is another standard we take pride in running here at ATC. Like other corrosion tests GMW 14872 is performed to evaluate accelerated corrosion effects on assemblies and different components. A combination of cyclic conditions provides the right environment for this type of accelerated corrosion. It takes 24 hours to complete one full cycle under these conditions which include three 8-hour stages: an ambient stage which has frequent sprays of solution, humid stage which allows for a higher humidity followed by a dry stage. There are two choices when running the cycle on the weekends. Option one is to continue with the normal three stages that are run during the week days and option 2 is an ambient stage for the full 48 hours. Excluding weekends calls for a longer test duration as the accelerated corrosion process is not in effect.

The GMW 14872 solution is comprised of Sodium chloride (NaCl), calcium Chloride (CaCl2) and Sodium bicarbonate (NaHCO3). A big part of running a GMW 14872 test is the mass loss data collection. Mass loss coupons are special steel chips that have been tested thoroughly to measure the corrosivity of the test. Based on the variation of test chosen from the variety of test selections a specific mass loss chart is to be followed. There are two methods to choose from (Method 1/2, Method 3) followed by the vehicle area which corresponds to Underbody (UB), Underhood (UH), Exterior (EXT), Secondary Surface (SS) and Interior (INT). The number of salt sprays can vary for each vehicle area as certain areas are more exposed to environmental corrosion than others. Based on the number of sprays per cycle along with a choice of the five exposures (A – E) a mass loss value is obtained. Each of these values has a plus/minus range which can conclude a test if the mass loss target is reached. This mass loss value is taken from measuring the weight of the sample prior to exposure from the weight of the samples after it has been exposed and rid of all corrosion until bare metal is present.

Testing Certificate # 2563.02

Our lab is accredited by A2LA.Scope

A2LA Letter of Accreditation (PDF)

Benefits of ATC Test Lab

A2LA Accredited Test Lab

Many manufacturers want to avoid hiring an accredited professional to conduct their sophisticated testing. By contracting ATC Test Lab you can avoid hiring and training costly specialized employees and equipment to conduct an array of tests.

Our experienced laboratory technicians understand the nature of each test, including GMW 14872. They are able to quickly detect product failure or unusual corrosion.

Specialized Testing Equipment and Chambers

ATC has new state of the art equipment to perform the most advanced testing. We have over 1200 Cubic Feet of testing space available, and the largest testing chambers in the world.

By contracting us, you can save money on new costly equipment, maintenance, and down time. You can size and scale your tests based on your level of production.

Receive Photographs and Updates

The best way to monitor your products during the testing process is though digital photography. ATC Test Lab offers high resolution photos at your requested intervals. The use of photographs can help you save money if you need to stop the test early due to product failure or unusual corrosion.

GMW 14872 Cyclic Corrosion

Exposure Testing Chamber at ATC Test Lab

GMW 14872

Cyclic Corrosion

Exposure Testing

Cyclic Corrosion

Exposure Testing

ATC Test Lab is the Largest Contract Corrosion Test Lab.

- We have over 1200 cubic feet of testing space available.

- Large testing chambers

- Our lab has state of the art equipment to perform the most advanced testing.

- Experienced laboratory technicians conducting your tests.